What is anti corrosion tape is a critical question for industries that rely on metal assets such as pipelines, valves, and steel structures. Corrosion is a silent but costly threat, causing premature failures and billions of dollars in maintenance and replacement expenses worldwide.

Anti corrosion tape—also commonly referred to as anticorrosion tape—is a specialized protective wrapping material designed to prevent corrosion by forming a durable physical and chemical barrier between metal surfaces and corrosive elements such as water, oxygen, salts, and industrial pollutants. In practical terms, the anti corrosion tape meaning refers to a tape-based corrosion protection system that seals metal surfaces and significantly slows or stops the corrosion process.

Unlike liquid coatings, anti corrosion tape is easy to apply, requires no curing time, and delivers immediate protection, making it especially suitable for pipeline projects and on-site repairs.

To clearly understand how anti corrosion tape works, it is important to examine the core protection mechanisms used in anticorrosion-tape systems.

Anti corrosion tape creates an impermeable shield that blocks moisture, oxygen, and electrolytes from reaching the metal surface. Since corrosion cannot occur without these elements, the tape effectively stops rust at its source.

The pressure-sensitive adhesive conforms tightly to surface irregularities, weld seams, and joints. This sealing action eliminates gaps where corrosion typically begins, which is especially important in pipeline applications.

Many anti corrosion tapes provide excellent electrical insulation, disrupting electrochemical reactions that accelerate corrosion in buried or underground pipelines and steel structures.

Together, these functions significantly extend the service life of metal assets in demanding environments.

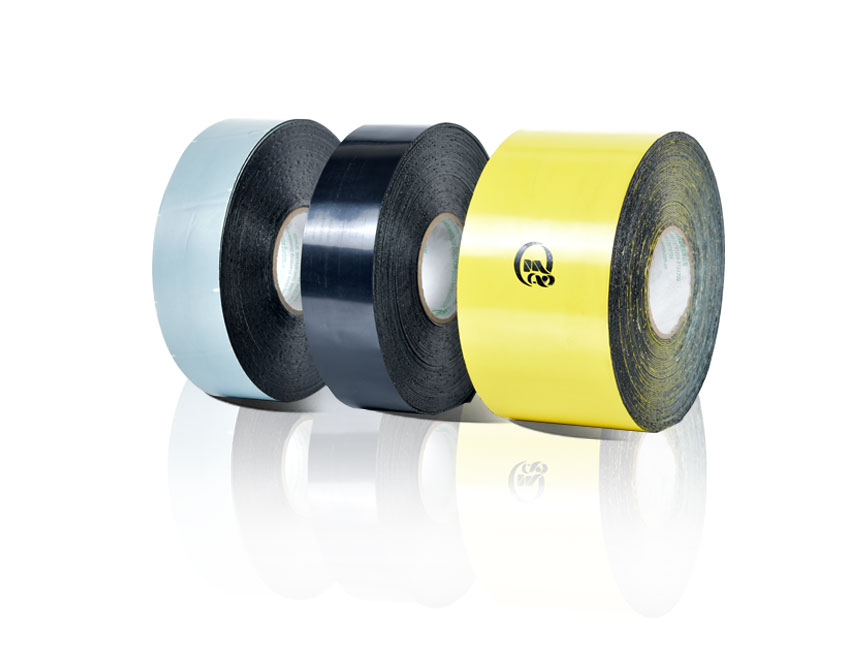

Anti corrosion tapes are engineered for durability, flexibility, and resistance to mechanical and environmental stress. Most anticorrosion-tape systems consist of two main components: a backing material and an adhesive layer.

There are several types of anti corrosion tape designed to meet specific environmental and operational requirements.

Selecting the correct tape depends on temperature, exposure conditions, soil chemistry, and pipeline service requirements.

|

|

|

Choosing tape over traditional liquid coatings offers several distinct advantages:

Anti corrosion tape is widely used across industries that require long-term metal protection, particularly for pipeline systems:

Its versatility allows reliable performance in both harsh outdoor environments and controlled industrial settings.

Understanding what is anti corrosion tape, along with its materials, types, and working principles, is essential for preventing costly corrosion damage in pipeline and industrial applications. Choosing the right anticorrosion-tape system can significantly extend asset life and improve operational reliability.

Looking for reliable pipeline protection?

Quanmin Plastic offers high-quality anti corrosion tapes designed to meet rigorous industrial standards. Contact Quanmin Plastic today to explore professional-grade solutions tailored to your application needs.